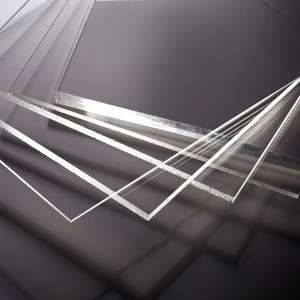

Polycarbonate, sometimes referred to as Lexan, is twice as light and 250 times stronger than standard glass and is therefore widely used for replacement glazing. In this blog, we’re going to take a look at the advantages and disadvantages of polycarbonate.

Key polycarbonate advantages

Fire-resistant

Vandal-proof

Hardwearing

Insulating

Lightweight

Easy to machine

Polycarbonate disadvantages

Sensitive to scratches if misused

Advantage: polycarbonate is fire-resistant

Unlike acrylic sheet, polycarbonate is resistant to fire and has a fire rating of B1, which means that the material will not burn with an open flame. Polycarbonate is actually self-extinguishing.

Advantage: resistant to vandalism

Polycarbonate is virtually unbreakable and vandal-proof, making it the ideal choice of material for safety glazing. Examples include shelters, bicycle sheds, machines and technical products, illuminated signs and marine glazing.

Advantage: sustainable

Polycarbonate also scores highly in terms of sustainability. It has a long service lifespan and the panels are fully recyclable. Our polycarbonate sheets are also resistant to UV rays, making them suitable as a sheet material for exterior applications. Polycarbonate is perfect for a greenhouse, a boat window, basketball backboards or a terrace canopy.

Advantage: insulating

An important advantage of polycarbonate is that it retains heat very well so is ideal for greenhouses. A polycarbonate greenhouse creates an optimal microclimate for your plants.

Advantage: light in weight

Polycarbonate sheets are twice as light as standard glass. This makes it very easy to work with, especially for a project such as installing a patio canopy.

Advantage: easy to process

Polycarbonate is processed in in the same way as acrylic sheet. Whereas acrylic may sometimes melt if machined at too high a speed, there is no chance of this with polycarbonate. This material is stronger so that the risk of breakage is even lower than with molded acrylic sheet. Polycarbonate can be sawn, milled, engraved, drilled, bent (hot), glued and polished in the same way as acrylic sheet.

Disadvantage & Solutions: Sensitive to scratches and how to remove them.

The main disadvantage of polycarbonate is that it isn’t resistant to scratches. For example, if a branch should happen to fall on a patio canopy made of polycarbonate, it may be scratched. This problem can be solved by polishing the polycarbonate which will remove any scratches.

Visit ALL our blogs at our BLOG tab.

Comments